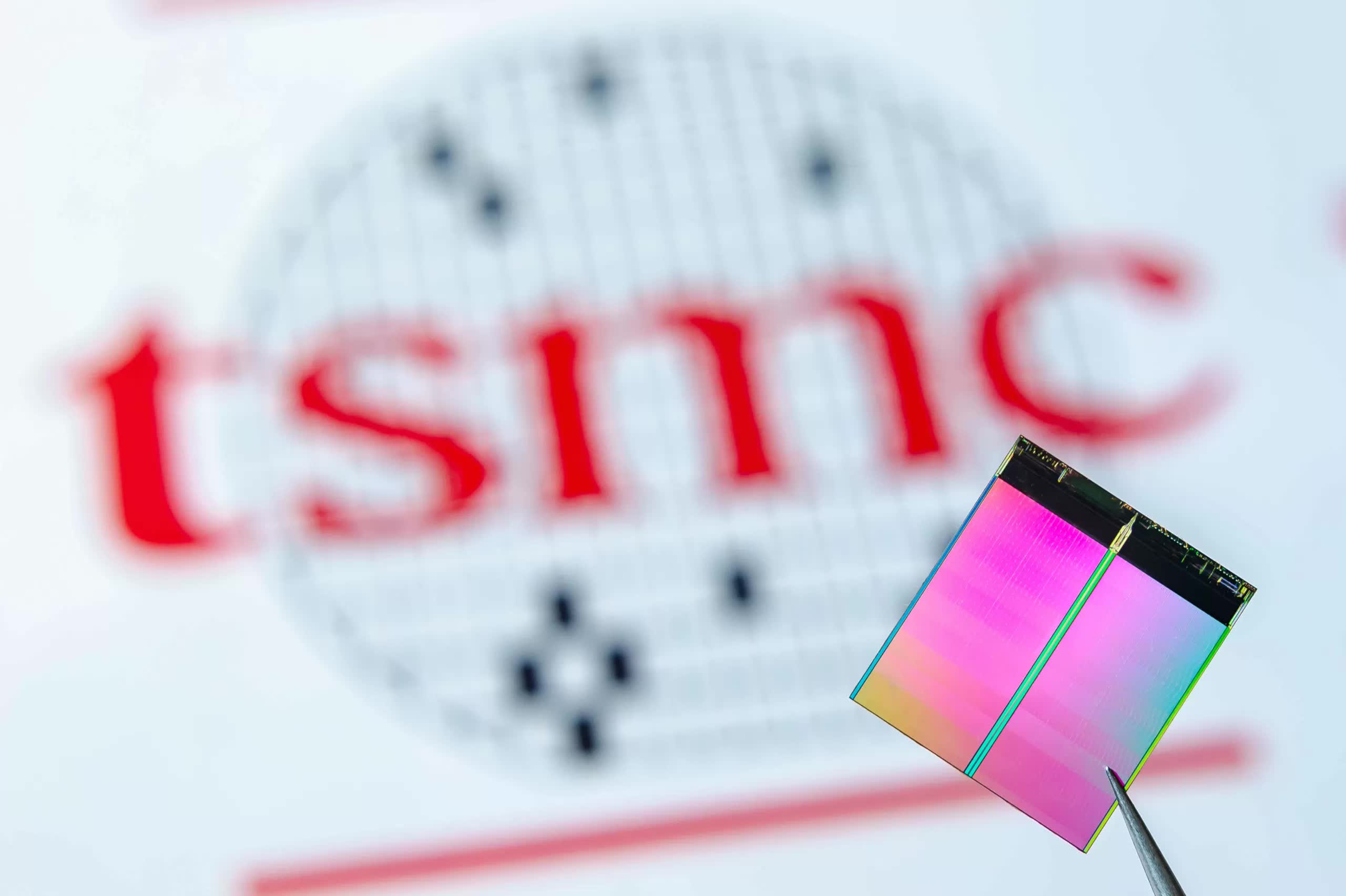

In brief: We’re in the middle of a global economic slowdown that has hit tech companies especially hard, but it seems nobody told TSMC. The world’s largest contract chipmaker saw its November revenue increase 50.2% year-on-year to reach $7.27 billion, and a lot of it was thanks to Apple.

Falling demand, China’s Covid Zero policies, the rising cost of living, and recession fears have made 2022 a bad year for tech giants. Demand for everything from smartphones to PCs has fallen, and mass layoffs have become a sight that is regular

TSMC has actually bucked the trend by significantly more than doubling its product sales in November—compared to a earlier—reaching $7.27 billion year. That puts the company on track to hit its estimate that is fourth-quarter of $19.9 billion and $20.7 billion.

Much of TSMC’s great one-fourth originated from providing the A16 SoC utilized in the iPhone 14 Pro and 14 Pro Max. Apple, currently TSMC’s biggest consumer, stated final thirty days so it would buy potato chips through the provider’s United States facilities, decreasing Cupertino’s reliance on Asia. We also heard that the* that is( giant will begin manufacturing on a 4nm process in its Arizona fabs in 2024—an upgrade from the previously planned 5nm wafers—following a decision that was reportedly encouraged by Apple.

Some analysts wonder whether TSMC will be able to keep its run of good fortune going next year when orders could decline. However, the company reportedly plans to raise wafer that is 3nm by 25 % over 5nm to $20,000, that should improve its main point here. The 2023 iPhone 15’s A17 Bionic chip should be made regarding the process that is 3nm and Apple has already agreed, albeit reluctantly, to TSMC’s price hike.

At an event attended by Joe Biden earlier this TSMC confirmed it would expand its building and manufacturing efforts within the US week. The development will discover $40 billion allocated to two fabs in Arizona, a growth through the formerly prepared $12 billion financial investment. The website will generate tens and thousands of tasks and also have a manufacturing that is total of 600,000 wafers each year.