[ad_1]

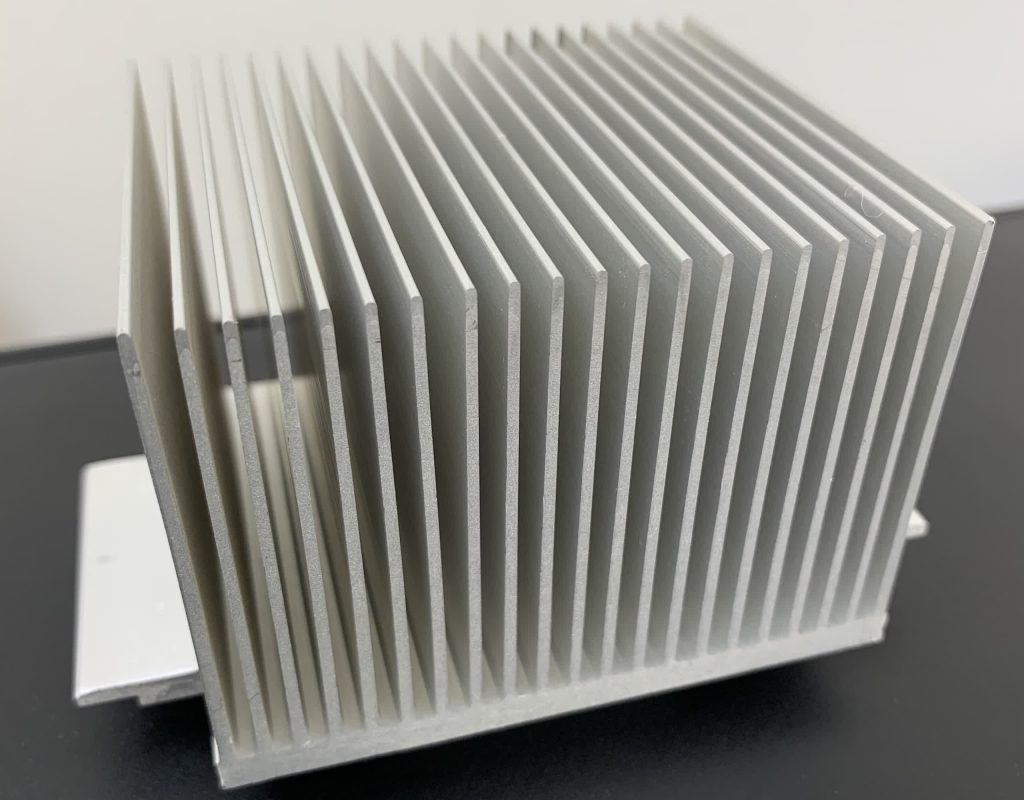

In context: Heatsinks are important in any laptop and plenty of digital gadgets. As CPUs and GPUs have gotten quicker and warmer over time, heatsinks have developed and are available many sizes and shapes. Some are large, just like the one within the PlayStation 5 (some are even larger). Others are small, like those used on an M.2 SSD.

Regardless of measurement or form, the best way they’re manufactured is fairly cool (no pun meant). There are typically 5 completely different processes to make a lot of the normal heatsinks we use at present — casting, milling, extrusion (pushing scorching steel by a die), 3D printing, and skiving (slicing the steel into slices, additionally known as scarfing).

While the video just isn’t new, thermal resolution producer Zaward has an excellent instance of the skiving course of on its YouTube channel (beneath). Here it’s carving massive heatsinks from a single block of aluminum, however the course of works the identical for copper.

First, engineers lubricate a big steel block and place it in a skiving machine. A management panel tunes the blade for desired fin thickness and different specs. Once the machine begins processing, the skiver shaves the steel downward at an angle.

On Zaward’s machine, the highest a part of the blade pushes the fin right into a vertical place as the underside half cuts the following slice concurrently. As you possibly can see within the second video from Reddit (beneath), some skiver blades reduce after which carry to bend the fin.

Regardless of the kind of machine, the third step is dissecting. A special blade cuts the lengthy block of uncooked heatsinks into the specified lengths. As you possibly can think about, all this steel slicing leaves burrs and sharp edges. So the uncooked heatsink blocks are despatched by a grinder to take away these imperfections. The grinding course of additionally shaves down the surplus steel from the underside of the heatsink to make it the specified top.

Once it is cleaned up, the product is prepared for packaging and is shipped to OEMs that manufacture something from PCs to satellites. It’s a reasonably neat course of that many by no means get to see.

[ad_2]