The huge picture: By now, many of us are acquainted with the truth that TSMC is, definitely, the essential able semiconductor maker on earth, while using the requires when it comes to business and geopolitics. And since this reality establishes in, many individuals being asking us exactly how did they get so excellent?

There tend to be numerous great records of the procedure, the newest of which is* that is( (which is very good), that cover the narrative of TSMC’s rise, but we think the question really goes to deeper fundamentals. What capabilities does TSMC have that others lack? And can anyone else build those? Not surprisingly, there is no answer that is simple this concern, but we believe there are some facets that actually stick out.

Editor’s Note:

Guest author Jonathan Goldberg could be the president of D2D Advisory, a consulting firm that is multi-functional. Jonathan has developed growth strategies and alliances for companies in the mobile, networking, gaming, and software industries.

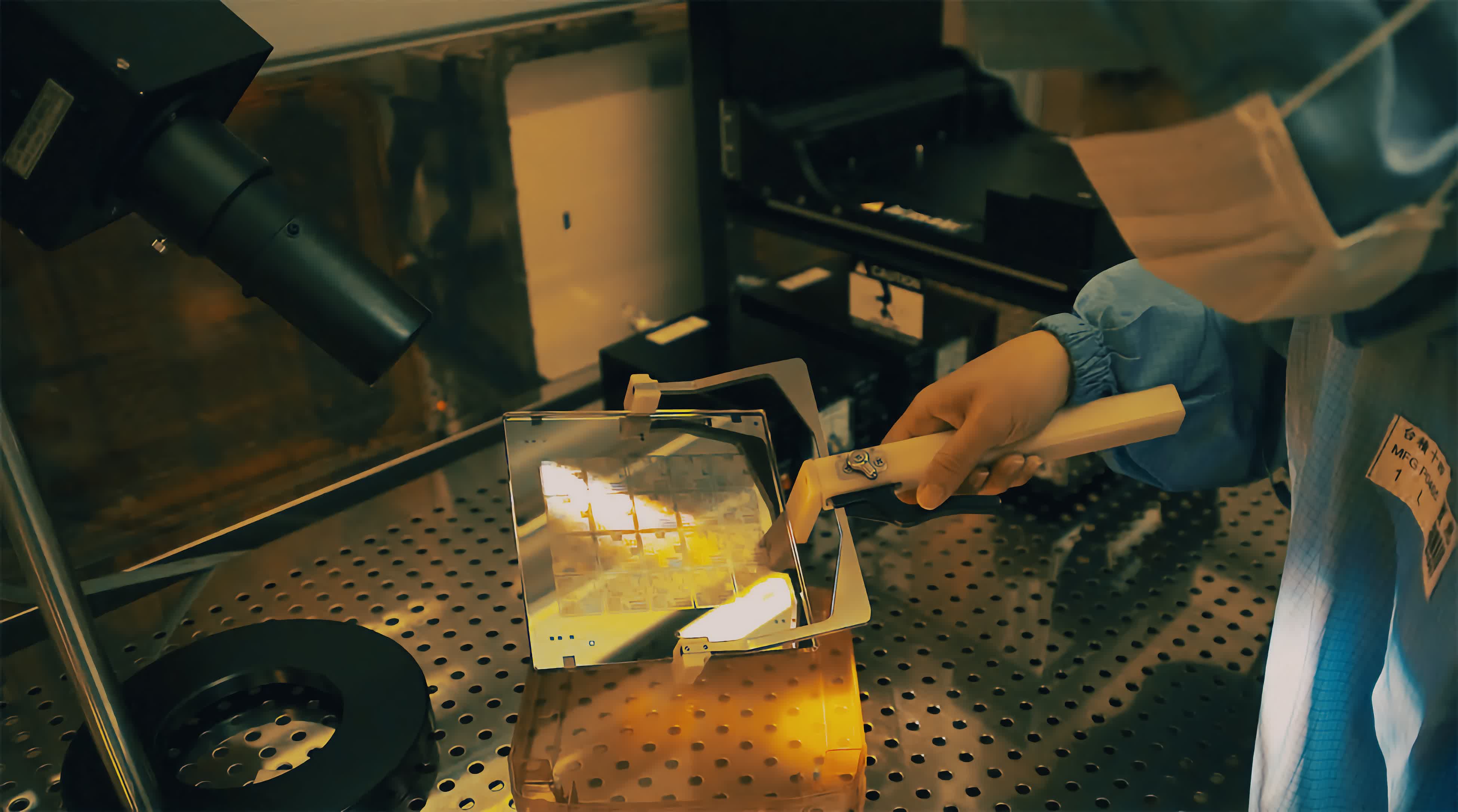

It is important to understand that much of TSMC’s current advantage rests in intangibles. Everyone else can buy the equipment that is same. And their particular success isn’t the results of one wizard. China’s SMIC has poached a huge selection of TSMC staff over time, to no avail. Nor could be the response money — creating an fab that is advanced incredibly expensive, but many countries have sunk vast fortunes into futile attempts.

TSMC’s Advantage rests in years of process and learning development

TSMC’s advantage rests in several years of understanding and procedure development. They learn how to prepare processor chip styles for production, develop all of them, and a lot of notably fix the bugs that are inevitable appear. Most importantly, they are able to capture and retain all this learning, so they can do all of this at immense scale, repeatedly.

To be fair, TSMC has gotten an boost that is immense the us government of Taiwan. The federal government offered direct subsidies TSMC that is allowing to the best machines available. This was incredibly important in the early days of the company, but remained important for long afterwards. As we will see, a part that is big of tale could be the durability and time scale of TSMC’s development.

A 2nd important aspect is the suppression associated with New Taiwan Dollar. The NTD has actually exchanged at around a 30% rebate towards the United States buck because the 1990’s. Everyone does know this, however the United States federal government has not acted with this money manipulation, mostly being an work to aid a local ally — consider Brad Setser’s work to get more with this.

Some will believe this isn’t crucial – TSMC costs all product sales in bucks, as well as its biggest cost, its gear, is perhaps all denominated in United States dollars aswell. But that overlooks capital that is human. The bulk of TSMC’s employees are based in Taiwan, and paid in NT, so the company is afforded a discount that is massive their particular wages.

All Those intangibles we mentioned above are captured in the company’s human capital, which the ongoing company has paid at a discount, which itself has compounded over 20 years. It is hard to overstate the importance of anything that compounds for that that is long

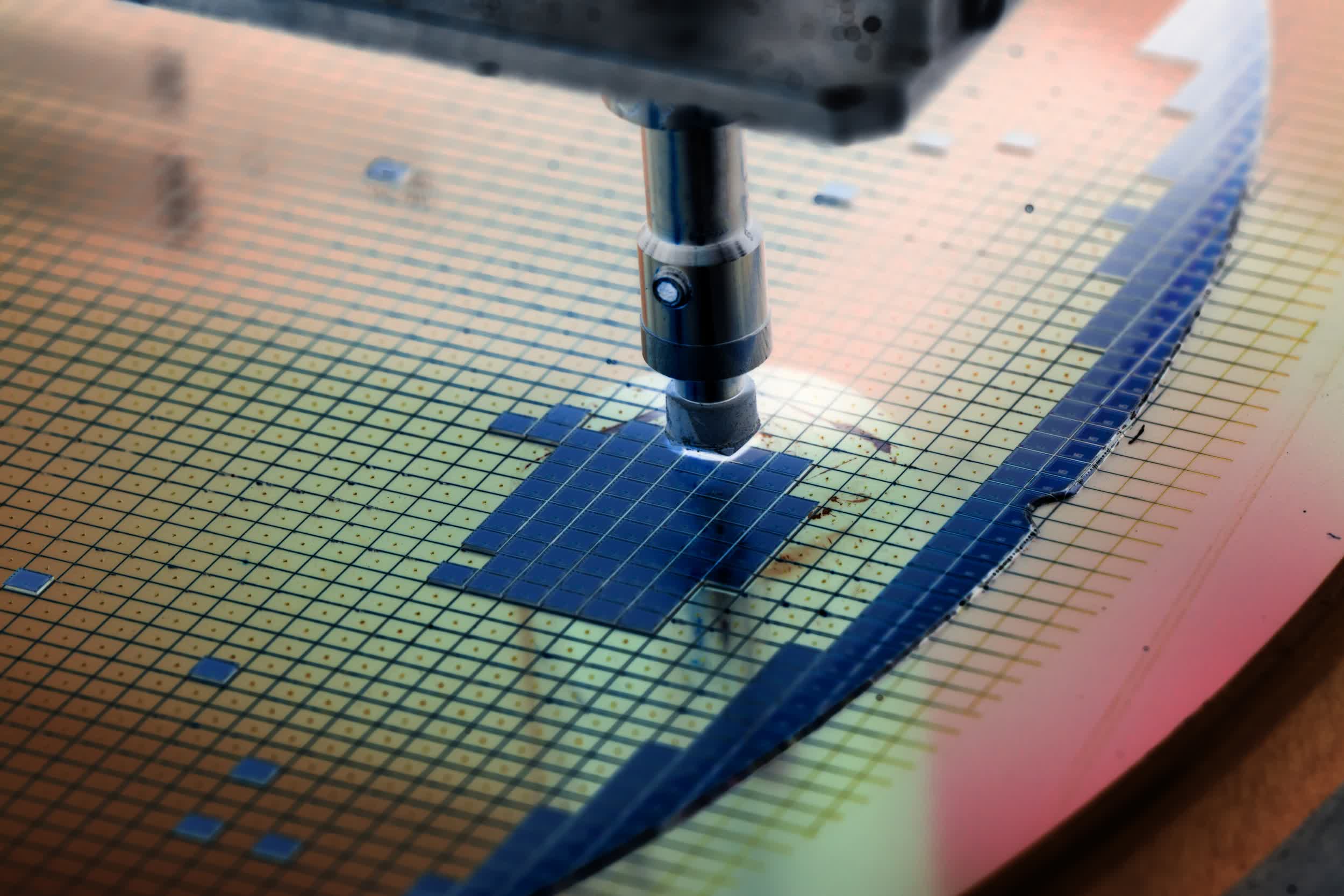

FinallyTSMC creates more silicon wafers than someone else, from a margin that is considerablePractice, and perhaps most importantly, TSMC produces more silicon wafers than anyone else, by a margin that is considerable. It contributes to improvement and TSMC gets more training than someone else.

Everyone might seem counter-intuitive, but semis production is really as art that is much science.Again else can access the machines that are same TSMC, however when your production procedure is premised on continuously pressing the envelope of what’s feasible, there is absolutely no handbook to describe how to handle it. TSMC’s amounts within the years have actually permitted all of them to build all of the processes and understanding basics needed seriously to forward keep moving faster than anyone else.

, this factor is self-reinforcing.ThisTSMC gets to nodes that are advanced everybody else and therefore improves yields quicker, affording all of them the capability to advance once again, and once again. The appears abstract, but start thinking about that each chip that is new is going to encounter bugs when it is first manufactured.

All TSMC engineers have likely seen those bugs already and can address them quickly.There of this provides TSMC not only with important advantages in capabilities, but also in terms of economics.

All are plenty of places in the world with the ability to produce chips on leading edge processes, and give those academics time that is enough often will produce a fantastic wafer, but TSMC will get here quicker plus in huge amount.It with this would be to state, that it’s not likely that anybody can undoubtedly meet up with TSMC any time soon. And took all of them decades to construct these processes up. Taiwan this helps partially explain why TSMC is now willing to build advanced fabs outside They. Arizona know that their fabs in Japan and Germany and Taiwan and wherever are going to remain dependent on the company’s deep expertise back in The.

US may get a edge that is leading, but that will not indicate the usa can definitely do exactly what TSMC does.(*)